Avviso pubblico della Regione Toscana per l'assegnazione di contributi ai datori di lavoro privati a sostegno dell'occupazione nel periodo 2018-2020

31/12/2021

La Topcast S.r.l. ha ricevuto nel 2021 dalla Regione Toscana un totale di 12.000,00 euro come contributi ai datori di lavoro privati a sostegno dell'occupazione nel periodo 2018-2020

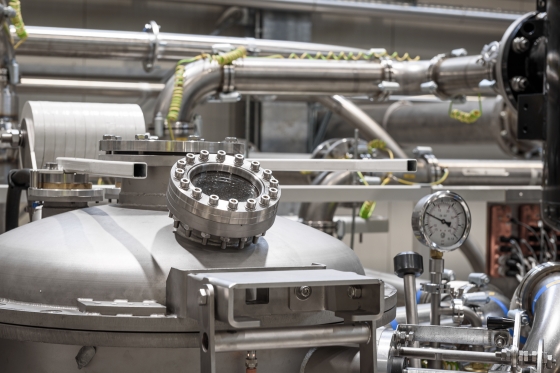

TMA-G – Gas Metal Atomizer

11/11/2021

The new section of TMA-G – Gas Metal Atomizer is now online Check the video for the new T-VIGA models for producing stainless steel, Ni-based or MoCrCo powders

TCC45-35-7000cc Vacuum Induction Continuous Casting Plant

09/07/2021

Watch our brand new video of TCC45-35-7000cc Vacuum Induction Continuous Casting Plant For additional info, please refer to > TCC - Vacuum Continuous Casting Machines

Vacuum Induction Continuous Casting Machines - TCC-XL

12/03/2021

This new video is about our TCC-XL Vacuum Induction Continuous Casting Machines Please refer to > induction Melting Furnaces

Investment Fund tender

01/02/2021

TOPCAST participated in the Regional Operational Program (POR) of the European Regional Development Fund (ERDF) 2014-2020 with the Investment Fund tender project.

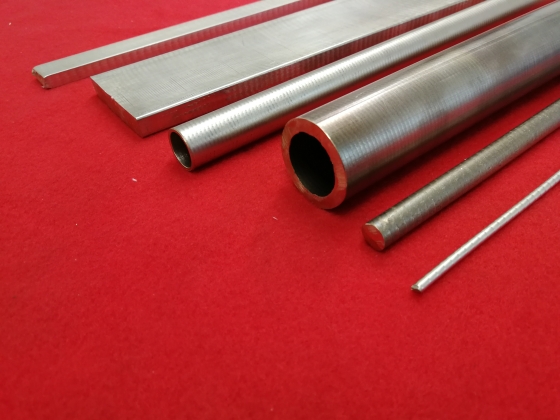

Vacuum Continuous Casting Machines TCC

04/01/2021

Watch the new video of our Vacuum Induction Continuous Casting Machines TCC. Vacuum Continuous Casting machines have been design with the most up-to-date technologies to give you semi-finished products with the best quality and in the shortest time. Please refer to > TCC - Vacuum Continuous Casting Machines

CAD Implementation

01/01/2021

Project co-financed by European Regional Development Funds (ERDF) for Tuscany POR-FESR 2014-2020 ACTION 1.1.2 TOPCAST S.R.L benefited from a contribution of € 25,700.00 under the POR-FESR Tuscany 2014-2020 ACTION 1.1.2 Innovation notice A. The investment program aims at obtaining a competitive advantage thanks to the introduction of business innovation tools: Introduction...

Topcast 200kW twin heads induction melting furnace

15/09/2020

This video describes a full twin-head melting system based on a double Topcast TMF200-RI4 Induction Melting Furnace. Furnace tilting is remotely controlled and hydraulic driven. Temperature may be controlled with an infrared pyrometer. Power may be switched between the two melting stations. An optional power supply controller allows the power sharing between the...

Metal Gas Atomizer TMA-G

07/03/2019

Watch the new video of our Gas Atomizers TMA-G. TMA-G is a family of gas atomizers designed to produce metal powders of rounded and regular shape, to be used in many industrial, chemical, electronics and rapid prototyping application (additive manufacturing) as SLM (Selective Laser Melting) and EBM (Electron Beam Melting). Please refer to > Metal Atomizer >>...

Manufacturing gold and silver ingots with an automated melter Topcast TIP12

02/05/2018

In this video you can see the manufacturing process of making gold ingots by a Topcast TIP12 Ingot Production Furnace. 1. The process starts with the insertion of the precious alloy into the mold put on a precision scale. 2. The mold is inserted into the furnace. 3. The alloy charge is heated and melt into the mold by induction. 4. The ingot solidifies in a...

TCC - Topcast introduces the new Vacuum Continuous Casting machines!

20/04/2018

Topcast is pleased to introduce the new TCC Vacuum Casting Machines. The TCC casting machines have been designed with the most up-to-date technologies to give you semi-finished products of the highest quality and in the shortest time. With just one machine, you will be able to get the semi-finished product you desire, such as wires, plates or pipes. All TCC models...

New Topcast headquarters!

26/02/2018

Visit our new headquarters in Via Leopoldo di Toscana 9, 52048 Monte San Savino (Italy)

Making gold and silver grains under protective atmosphere with a Topcast TVC-XL-G

26/08/2017

Topcast TVC-XL-G furnaces are used to produce high quality metal grains in a protective atmosphere of Argon or Nitrogen. Process begins with the loading of the precious metal in the crucible; then you can see the display showing process variables. Then the charge is melted by induction heating. Then the shutter is raised and metal is poured into...