Vacuum Melting & Casting

Ferrous Metals

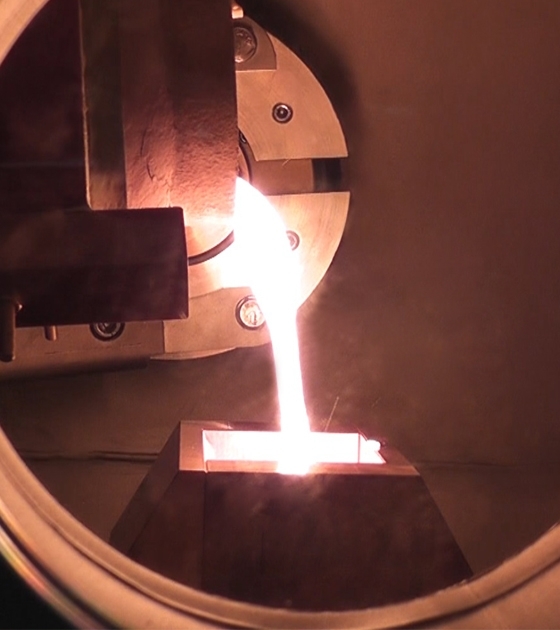

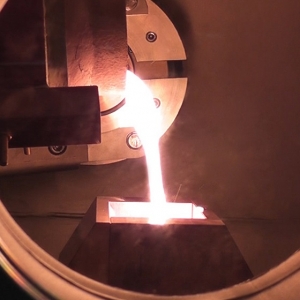

Vacuum investment casting is the process used in lost-wax technique to get a metal replica from wax or resin patterns.

The pattern is designed and then built in wax or resin by different equipment as CNC, 3D printers, by means of wax injection in a mould, or even manually.

You may use either investment molds or metal permanent molds.

Furnaces or complete foundries setup for the casting of Steel, Fe and Nickel-based alloys can be supplied for any application.

- TVC-XL vacuum casting machines (dual chamber system) to get detailed and porosity-free surfaces;

- TCE furnaces vacuum centrifugal casting for high high metal yelds, thin and large surfaces, difficult and detailed parts;

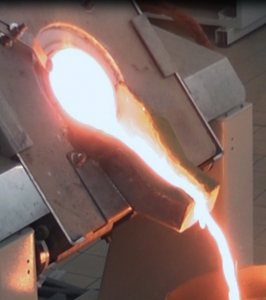

- TVM - Vacuum Induction Melting Furnace (VIM) pouring by gravity, either from a cold crucible (skull melting) per pristine meltings, or hot crucible when you need overheating and high energy efficiency;

- FCC furnaces for wax / resin removal and refractory mould baking.

Induction Melting

Ferrous Metals

IGBT-based proprietary design, high-performance induction generator is equipped with soft-switching and frequency automatic tracking technology.

Powders / Atomizer

Ferrous Metals

For ferrous metals powder production, TOPCAST has developed water and gas Atomizing Furnaces, complete with cyclone filtering system and dryer for a key in hands solution.

Recovery

Ferrous Metals

For ferrous metals recovery, alloy homogenization and scraps melting, TOPCAST proposes its wide line of Medium Frequency Induction Melting furnace starting from 5 kW to 500 kW.

Joystick assisted crucible tilting mechanism are provided with both, electro-mechanical or hydraulics control.

Assay & Test

Ferrous Metals

For ferrous metal assaying TOPCAST proposes a specific vacuum centrifugal casting machine for XRF analysis sample preparation.

Small melting furnaces with manual extraction of the crucible are also available for the homogenization of steel samples coming from a scrap batch.

The resulting ingot may be analyzed by XRF equipment.

Vacuum Melting & Casting

Non Ferrous Metals

Vacuum investment casting is the process used in lost-wax technique to replicate in metal a wax or resin pattern.

The shape is designed and then built in wax or resin by different equipment as CNC, 3D printers, by means of wax injection in a mould, or even manually. You may use either investment molds or metal permanent molds.

Furnaces or complete foundries setup for any casting application of magnesium, alumunium, bronze and brass .

- TVC-XL vacuum casting machines (dual chamber system) for particular jointed and free of porosity;

- TCE centrifugal vacuum casting machines for high performance levels of the metal, thin and large surfaces, difficult and detailed parts;

- FCC burnout furnaces for wax / resin removal and refractory mould baking.

Induction Melting

Non Ferrous Metals

IGBT-based proprietary design, high-performance induction generator is equipped with soft-switching and frequency automatic tracking technology.

Powders / Atomizer

Non Ferrous Metals

For non-ferrous metal powder production, TOPCAST has developed water and gas Atomizing Furnaces, complete with cyclone filtering system and dryer for a key in hands solution. Bronze powders are commonly used in SLM systems for 3D rapid prototyping,

Recovery & Refining

Non Ferrous Metals

For use in processes like non-ferrous metal refinery, recovery, alloy homogenization and scraps melting, TOPCAST proposes its wide line of Medium Frequency Induction Melting furnace ranging from 5 kW to 500 kW.

Joystick assisted crucible tilting mechanism is provided with either electro-mechanical or hydraulics control. Hand-whell tilting also available on smaller furnaces.

Assay & Test

Non Ferrous Metals

For nonferrous metal assay and test, TOPCAST proposes a specific pressure over vacuum casting machine for XRF analysis sample preparation.

Small melting furnaces with manual extraction of the crucible are also available for the homogenization of the samples coming from a scrap batch.

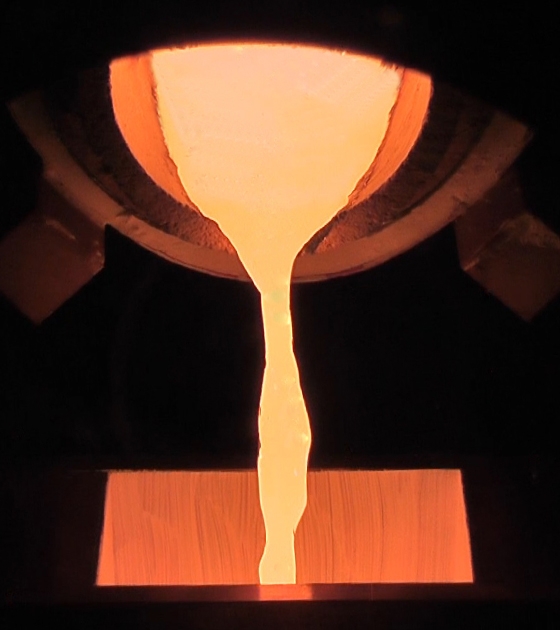

Vacuum Melting & Casting

Precious Metals

Vacuum investment casting is the process used in lost-wax technique to get a metal replica from wax or resin patterns.

The pattern is designed and then built in wax or resin by different equipment as CNC, 3D printers, by means of wax injection in a mould, or even manually.

You may use either investment molds or metal permanent molds.

Furnaces or complete foundries setup for casting of Au, Ag, Pt or Pd alloys can be supplied for any application, including vacuum melting into permanent molds.

- TVC Vacuum casting machines (dual chamber system) to get detailed and porosity-free surfaces;

- TCE Centrifugal vacuum casting machines for high performance levels of the metal, thin and large surfaces, difficult and detailed parts;

- TVM Vacuum Induction Melting Furnace (VIM) pouring by gravity, to pour large ingots of Platinum and PGM alloys with reduced porosity;

- FCC Burnout furnaces for wax / resin removal and refractory mould baking.

Induction Melting

Precious Metals

IGBT-based proprietary design, high-performance induction generator is equipped with soft-switching and frequency automatic tracking technology.

Powders / Atomizer

Precious Metals

For precious metal powder production, TOPCAST has developed water and gas Atomizing Furnaces, complete with cyclone filtering system and dryer for a key in hands solution. Gold alloy powders and silver alloy powders are commonly used in SLM systems for 3D rapid prototyping of jewellery.

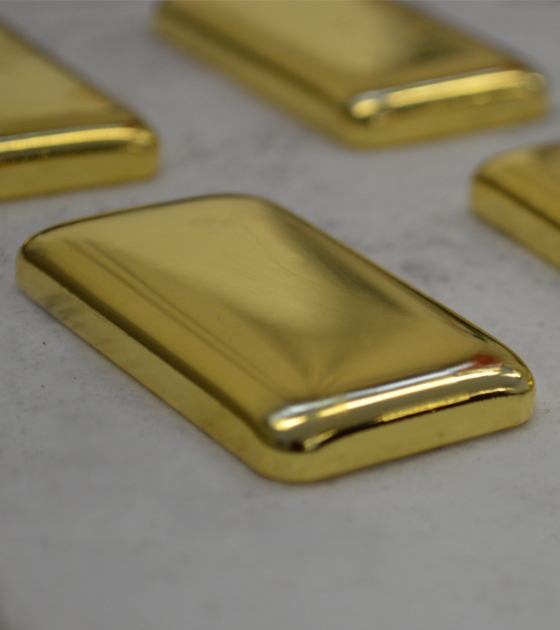

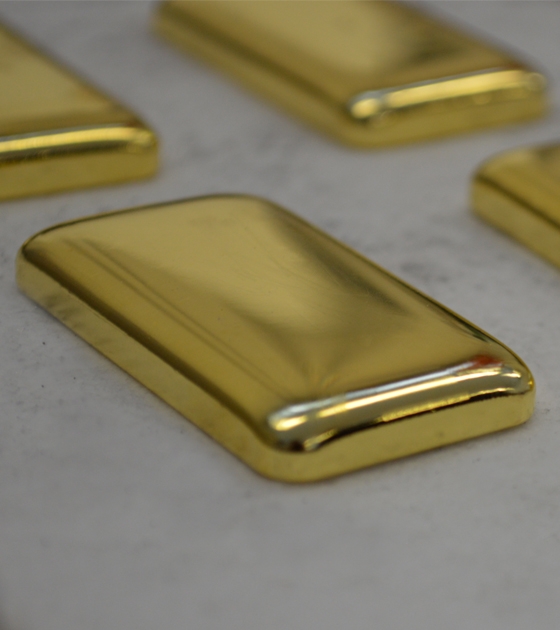

Ingots, Sheets, Rods, Tubes, Grains

Precious Metals

TOPCAST designs and manufactures vacuum and inert-gas furnaces for precious metal ingots, sheets, rods and grains production in batch production.

Recovery & Refining

Precious Metals

For the refinery and recovery of precious metals, precious ashes melting, alloy homogenization and scraps melting, TOPCAST proposes its wide line of Induction Melting Furnaces, starting from 5 kW to 500 kW.

Joystick-assisted crucible tilting mechanism is provided either with electro-mechanical or hydraulics control.

Supplies may also include water chillers, fume extraction systems and all ancillary equipment for foundries.

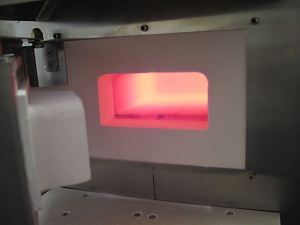

Assay & Test

Precious Metals

For precious metal assaying TOPCAST proposes a key-in-hand solution for cupellation assay lab. The offer includes:

- drill, precision balance and assay preparation mill;

- a fast and efficient induction cupellation furnace for assays on multiple sample at a time, capable of reaching the working temperature in very short times. To save energy, the oven can be switched off after work without compromising the heating system;

- separating hood for multiple assay and fumes scrubber;

- training of personnel in assay laboratory in the area of Arezzo, Italy.

Vacuum Melting & Casting

Titanium and Reactive Metals

Vacuum investment casting is the process used in lost-wax technique to get a metal replica from wax or resin patterns.

The pattern is designed and then built in wax or resin by different equipment as CNC, 3D printers, by means of wax injection in a mould, or even manually.

For Titanium and Reactive metals casting, used in fields like Aerospace, Automotive and Medical, TOPCAST proposes the following categories of furnaces:

- TCE - Vacuum Centrifugal Casting Machines for high metal yield, thin and large surfaces and challenging and detailed parts.

- TVM - Vacuum Gravity Furnace (V.I.M. system); available either for skull melting (cold crucible) for no melt contamination, or hot crucible melting for over-heating and high efficiency processes.

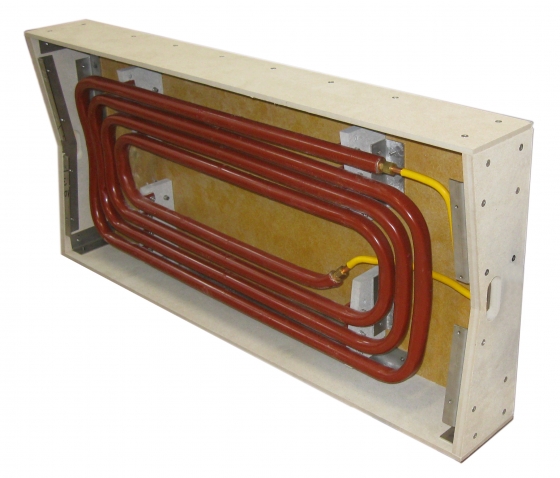

- FCC - Electrical Ovens for wax / resin removal and refractory mould baking.

Parts Heating - Cylindrical Coil

Induction Heating, Brazing and Soldering

TOPCAST develops systems of induction heating for brazing, annealing or welding of metal parts with many different configurations of the inductor, such as pancakes or cylindrical.

Applications range from the heating of large metal pipes up to coating and heat treatment.

The production range of generators is from 5 kW to 500 kW and from 1 kHz to 100 kHz.

Pipes Heating - Pancake Coil

Induction Heating, Brazing and Soldering

TOPCAST develops induction heating systems for metal parts brazing, annealing or soldering with many different induction heating coil configurations like pancake or cylindrical.

Large pipes heating for vary applications have been successfully implemented.

Induction Generators production line goes from 5 kW to 500 kW and from 1 kHz to 100 kHz.